Welcome toPrinceton Flighting Corporation

A Leading Manufacturer of

Auger Flighting for Agriculture and Industry

Based on 48 years of development of the Lenham range of cold-rolling strip mills, Princeton Flighting Corporation produces competitively priced continuous auger flighting unsurpassed for high output and long-lasting wear resistance.

While offering conventional helicoid flighting, we also offer Super-Edge™ flighting which benefits from a guaranteed minimum 30% (and as much a 50%) increase in steel thickness along the flighting outer edge where wear on all augers is concentrated. Super-Edge™ has for over 20 years been the performance-proven first choice both for OEM equipment and for auger repairs on farms nationwide.

Our R&D commitment has now yielded a further major advance in auger technology with the introduction of our patented Max-Edge™ flighting which lifts auger durability to a new level of excellence. Max-Edge™ provides a wide reinforcing band along the outer edge of the flighting which is DOUBLE the thickness of conventional flighting and equal to the raw material thickness before rolling. Max-Edge™ flighting is currently the specified component in most grain cart brands where high output and durability are essential and its performance is far in advance of all other continuous cold rolled flighting. Patent Nos. US9061345B2, 2894798, 2948392.

"Our diverse range covers the complete spectrum of auger flighting required in agriculture and industry. Our production method ensures close control of dimensional accuracy and we take great pride in the quality of flighting we produce."

As members of the Lenham Group, Princeton Flighting Corporation and Top Flite Corporation manufacture continuous helicoid flighting in both Carbon and Stainless steels on 14 state-of-the-art Lenham cold-rolling mills.

The third member of the Lenham Group, Flight Manufacturing Corporation, manufactures high precision Edge-Wound Helicoid Flighting and Sectional Segmental Flighting in mild steels. stainless steels and wear resistant steels to complete the full spectrum of flighting used in both agricultural and industrial applications.

With a comprehensive range of high quality products, priced competitively and delivered with speed and flexibility, our experienced personnel show their enthusiasm and positive motivation. We are a family oriented business operating in partnership with our customers for mutual benefit.

We hope you find our site interesting and informative and welcome your inquiries.

Super-Edge™ Helicoid Flighting

Super-Edge™ flighting is the product of our R&D program and is a major advance over standard helicoid flighting.

Super-Edge™ flighting provides a guaranteed minimum of 30% (up to 50%) increase in thickness at the exact location where the greatest wear occurs. Designed specifically to combat auger wear, the added strength is achieved with no increase in weight and it can be incorporated with no modification to existing auger specifications. The improvement in edge thickness is a quality feature visible to the purchaser of both new and rebuilt equipment.

This advance flighting combines dimensional precision with high quality surface finish rolled to CEMA standards and OEM specifications.

For over 20 years it has proven to be the first choice among farmers for all auger repairs. It is specified in the original equipment of major international brands. Super-Edge™ delivers lasting reliability in farm machinery nationwide.

Super-Edge™ Auger Flighting

Major Performance Improvements include:

- longer life augers

- high durability with added strength profile

- greater wear resistance over thickened tapered edge

- minimum 30% thicker outside edge over conventional helicoid flighting

- smooth inner edge finish for improved mounting operation

- no marked increase in weight, power requirements unchanged.

- fewer flighting repairs

Cupped Super-Edge™ Helicoid Flighting

The benefits of Super-Edge™ plus:

- up to 30 degree lean from vertical.

- greater grain retention within each pitch

- improved auger output

- helps to minimize "fines" degradation.

- preferred for optimizing output in grain carts

- ideal for handling seed grains at lower output speed

Process

The raised edge is formed integrally during the manufacturing operation and is not a strip attached by a secondary method.

Interchangeability

The introduction of Super-Edge™ Auger flighting to replace conventional flighting necessitates no design or product modification.

- 1/8"

- 3/16"

- 1/4"

- 5/16"

- 3/8"

- 7/16"

- 1/2"

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Short Pitch - where Pitch dimension is less than Outer diameter dimension

- Long Pitch - where Pitch dimension is greater than Outer diameter dimension

- Left Handed

- Right Handed

Immediate From Stock Mid-West Warehouse Locations

Our Illinois and Nebraska warehouses carry over 1,250 different sizes of flighting in various thicknesses to repair or upgrade worn flighting in combines, grain augers and all general farm equipment. Same day dispatch in 5 foot lengths by UPS/other carrier and in 10 foot lengths by truck line.

Conventional Auger Flighting

- 14 Lenham "state-of-the-art" cold rolling mills

- highly rigid, wear-resistant flighting

- manufactured from prime grade Carbon steel

- work hardened, tough & smooth surface finish

- superlative durability and output.

- production method ensures total control and dimensional accuracy.

- 1/8"

- 3/16"

- 1/4"

- 5/16"

- 3/8"

- 7/16"

- 1/2"

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Short Pitch - where Pitch dimension is less than Outer diameter dimension

- Long Pitch - where Pitch dimension is greater than Outer diameter dimension

- Left Handed

- Right Handed

Immediate From Stock Mid-West Warehouse Locations

Our Illinois and Nebraska warehouses carry over 1,250 different sizes of flighting in various thicknesses to repair or upgrade worn flighting in combines, grain augers and all general farm equipment. Same day dispatch in 5 foot lengths by UPS/other carrier and in 10 foot lengths by truck line.

Conventional Cupped Helicoid Flighting

The benefits of our Conventional Auger Flighting plus:

- up to 30 degree lean from vertical.

- greater grain retention within each pitch

- improved auger output

- helps to minimize "fines" degradation.

- preferred when optimizing output in grain carts

- preferred for handling seed grains at lower output speed

Ribbon Helicoid Flighting

We manufacture conventional "ribbon" flighting which is characterised by having an enlarged inner diameter using narrow raw material. Can be manufactured as a reinforced edge when welded to Conventional Helicoid Flighting.

- 1/8"

- 3/16"

- 1/4"

- 5/16"

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Short Pitch - where Pitch dimension is less than Outer diameter dimension

- Long Pitch - where Pitch dimension is greater than Outer diameter dimension

- Left Handed

- Right Handed

Stainless Steel Helicoid Flighting

We manufacture at Top Flite Corporation high quality conventional flighting from 304L & 316L grade stainless steel.

We hold a stock of standard sizes up to 12" outer diameter and custom roll to customer specifications.

The clean, bright surface finish provides hygienic, anti-corrosive delivery to a wide range of industries.

Stainless flighting has numerous industrial applications particularly in the handling of corrosive materials and within the food processing industry.

- 1/8"

- 3/16"

- 1/4"

- 304L Grade Stainless Steel

- 316L Grade Stainless Steel

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Left Handed

- Right Handed

Edge-Wound Helicoid Flighting

We manufacture Edge-Wound flighting at our sister company Flight Manufacturing Corporation.

This continuous helicoid is produced by winding over a mandrel such that there is minimal loss of thickness at the outer edge.

Forming features:

- heavy duty flighting on in-house built machines

- highly rigid, wear-resistant flighting

- production method ensures total control and dimensional accuracy.

- superlative durability and output

- particularly suitable for high-wear industrial applications

- available in prime Carbon and Stainless steels from coil strip or bar.

- thicknesses from 3/16" to 1" & outside diameters from 1.5" to 20".

- extremely close tolerances in both left hand and right hand configuration.

- 10 ga.

- 3/16"

- 1/4"

- 5/16"

- 3/8"

- 1/2"

- 5/8"

- 3/4"

- 1"

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Short Pitch - where Pitch dimension is less than Outer diameter dimension

- Long Pitch - where Pitch dimension is greater than Outer diameter dimension

- Carbon Steel

- 304 Stainless

- 316 Stainless

- Left Handed

- Right Handed

Sectional Flighting

We manufacture Sectional flighting at our sister company Flight Manufacturing Corporation.

Sectional flights are produced by forming metal plate into a Helix with precise outer diameter, inner diameter and pitch.

Forming features:

- Manufactured on in-house machinery

- available in thicknesses ranging from 3/16" to 1"

- flight thickness maintained constant from the inner edge to outer edge.

- sections with outer diameters ranging from 5" up to 72"

- variety of prime Carbon, Stainless and abrasion resistant steel grades.

- manufactured with holes, radius cuts, slots, tooth-cut outer-edge, etc., as required.

- 3/16"

- 1/4"

- 5/16"

- 3/8"

- 1/2"

- 5/8"

- 3/4"

- 1"

- Standard Pitch - where Pitch dimension is equal to Outer diameter dimension

- Short Pitch - where Pitch dimension is less than Outer diameter dimension

- Long Pitch - where Pitch dimension is greater than Outer diameter dimension

- Carbon Steel

- Grade 50 Steel

- A-36

- AR–400

- 304 Stainless

- 316 Stainless

- Left Handed

- Right Handed

Measuring Flighting

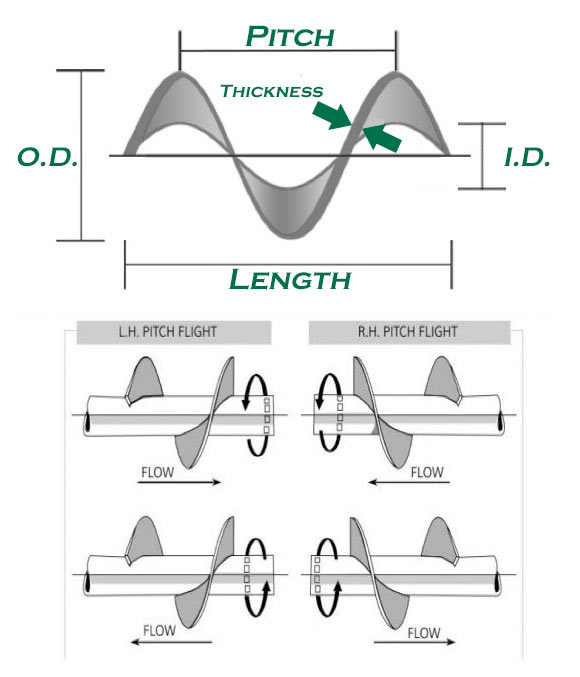

Pitch:

Pitch is the distance between each section measured at the outer edge parallel with the shaft.

Outside Diameter (OD):

This is the vertical distance from upper to lower outer edges of the flighting.

Inside Diameter (ID):

This is the hole size in the flight into which the center tube or shaft fits.

Thickness:

This dimension is measured at the shaft at the thickest part of the flight.

Length:

This is the length per piece.

Quantity:

This is the total number of pieces needed.

The Lenham Group

We are a privately owned group of companies which specialize exclusively in the development and production of precision auger flighting and the improvement of auger performance through technical innovation.

We have a highly skilled and dedicated team of personnel drawing upon over 35 years of flighting production experience.

We have the capacity and flexibility to meet and exceed our customer expectations.

We are pushing the boundaries of conventional wisdom in this field and setting new standards.

- 145 W. Progress Drive, Princeton, IL 61356

- ph: 1-800-832-6090 1-815-872-1431

- fax: 1-815-872-1705

- [email protected]

Longer lasting, high quality, cold rolled continuous helicoid flighting in carbon and stainless steels.

- 106 Grant Street, Aurora, NE 68818

- ph: 1-888-728-0969

- ph: 1-402-694-6536

- fax: 1-402-694-5636

- www.tfcflighting.com

- [email protected]

Longer lasting, high quality, cold rolled continuous helicoid flighting in carbon and stainless steels.

- 2750 Tradition Drive, Princeton, IL 61356

- ph: 1-800-579-9978

- ph: 1-815-876-1616

- fax: 1-815-872-1112

- www.flightmfg.com

- [email protected]

Sectional and Edge-wound flighting in carbon steels, abrasion-resistant and stainless steels.

Contact Princeton Flighting Corporation

Please feel free to use the information or form below to contact us with any questions, comments or requests.

- 145 W. Progress Drive, Princeton, IL 61356

- ph:1-800-832-6090

- ph: 1-815-872-1431

- fax: 1-815-872-1705

- [email protected]

* denotes required field